Fashion companies are constantly seeking innovative ways to enhance efficiency, reduce costs, and accelerate product launches. A digital design process has the potential to expedite these aspects and provide a significant competitive edge for brands, but they often struggle to implement it.

Today, fashion consumers are swiftly transitioning from conventional brick-and-mortar stores to online shopping. In order to align with their purchasing preferences in the digital realm, fashion companies must engage with their customers through digital platforms, utilising tools like digital showrooms and virtual dressing rooms.

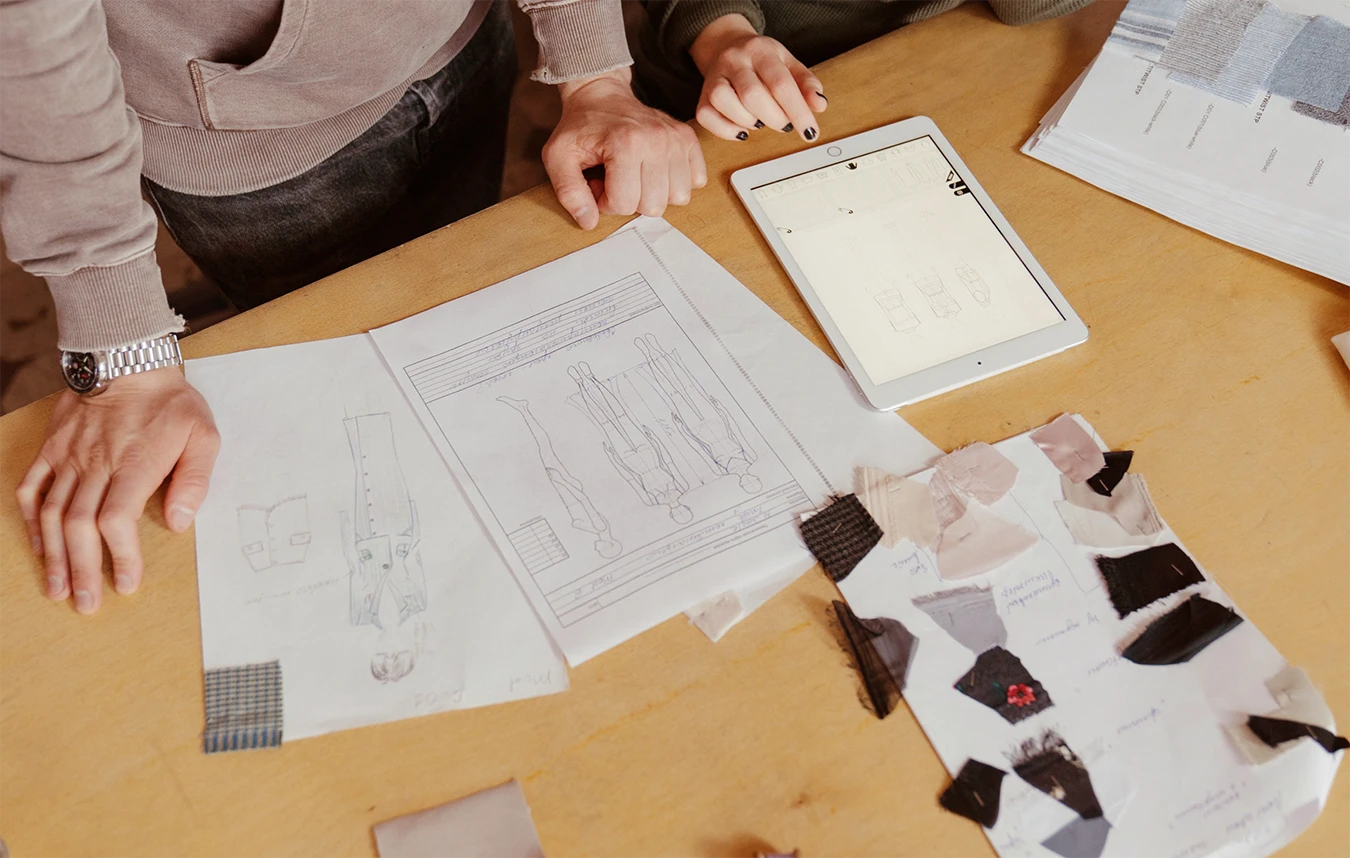

The potential of digital product development

By introducing a fully integrated digital product development process, companies can meet their customer needs, as well as gain many benefits internally. It accelerates the design process by allowing virtual prototypes to be created much faster than physical prototypes, enabling companies to respond swiftly to market trends and gain a competitive edge.

In addition, with improved accuracy, fashion companies can visualise the final product with precision, identifying and rectifying any flaws before getting into production. This helps in reducing costs, decreasing wastage, minimising errors, and increasing profits for fashion brands operating in an intensely competitive environment.

The emergence of 3D within product development

3D digital product development refers to the innovative process of creating and designing garments and accessories through virtual means. By leveraging advanced computer-generated imagery and simulation technologies, fashion professionals can visualise, prototype, and refine products in a three-dimensional digital environment. This transformative approach accelerates the product development lifecycle, fostering efficiency, sustainability, and unparalleled creative possibilities in the ever-evolving landscape of the fashion industry.

The flexibility provided by 3D product development enables designers to modify and refine designs without starting from scratch, accelerating adaptation to changing market demand. In addition, fashion companies now have the power to create realistic virtual models of their products, enhancing their pitch presentations to potential customers and partners, and increasing the likelihood of securing orders and partnerships. However, the implementation of 3D product development comes with a host of challenges.

Challenges involved in 3D product development

Many fashion brands are struggling with the transformation of developing new styles completely in 3D. While the benefits of this kind of product development are substantial, it is important to acknowledge the initial investment required in terms of integrating new systems and processes into the existing landscape, and the costs and time involved in change management. The most common challenges we see are:

System integration struggles

Integrating 3D product development into existing systems, such as Product Lifecycle Management (PLM), and replacing old tools with modern technology can be challenging. Take, for instance, the adoption of new fashion design software, such as CLO. This kind of specialised software needs to be implemented and materials need to be visualised in 3D with specific technology so that they look as realistic as possible.

Proficiency gap

Many fashion designers are used to working with 2D sketches and patterns. To design a garment in 3D, a high level of technical skills and expertise is required, which many fashion companies do not have in-house. This means that companies must rely on external providers or provide internal training, which increases costs and slows down the initial development process.

Time intensive development

For complex garments, developing a product in 3D can be time-consuming which delays the time to market for new products and puts pressure on already tight development timelines. Thus, transitioning to a new process can lead to resistance to change and reluctance to adopt new technologies.

Introducing 3D modular design and how to implement it

Major fashion companies can leverage 3D modular design, to benefit from the digital design process and simplify garment creation. This innovative approach to designing garments uses digital, pre-defined toolboxes for forms, fabrics, and trims to streamline the design and development process. This allows designers to use an already existing form as a starting point and to choose from materials that were already quality-proofed, which shortens the time to create a new style significantly.

At Metyis, our team of experts helps our partners implement 3D modular design by focusing on five key areas:

Building up a common logic

The way of designing and developing a garment varies vastly among different business units, product groups, and even teams. Hence, as a first step, a standard process needs to be identified that is valid across all design teams.

Streamlining and aligning the process

It is necessary to understand the differences per product group and to adjust or use additional tools to visualise the garment as realistically as possible. For example, the challenge for denim is to visualise the different washing so that additional steps are needed to create the new style in 3D.

Analytics and reporting

To define the right content for the toolboxes, several data analyses need to be compiled. For example, high-style coverage analyses inform consolidation workshops that identify commonly used materials and forms across styles and seasons. Real-time insights through reports and dashboards aid informed decision-making for adjusting or updating processes and toolboxes.

Setting up a robust governance structure

In the fast-paced fashion industry, continuous monitoring of processes and tools is crucial. For example, the strategic direction of the company or business unit might change to reach a new target group, which may require updates to the forms library and modular toolboxes. A dedicated steering board facilitates efficient decision-making to keep the process on track.

Driving the change

To facilitate a smooth transition, it is necessary to engage early on the different stakeholders like (pattern) designers and brand management. For that, it is crucial to have a continuous communication roadmap and offer sufficient training as working fully in 3D is an expertise that needs to be steadily built up within the company.

Implementing 3D product development to create impact

To stay ahead in the fast-moving fashion industry, it is crucial for fashion companies to embrace digital fashion and implement an integrated 3D product development process. This transition requires a strategic and comprehensive approach that addresses the challenges and maximises the benefits of digitalisation.

The high level 3D modular design process

Our team excels in navigating intricate tech implementation projects and crafting tailored strategies that bridge the gaps between teams and stakeholders in the fashion industry. Drawing from our extensive experience, we specialise in standardising processes, streamlining workflows, and incorporating specialised tools for diverse product categories, fostering practical visualisation and efficient development.

Leveraging our expertise in data analytics, we uncover insights from common materials, forms, and trims, bolstering real-time decision-making through insightful reports and dynamic dashboards. Our team can establish robust governance structures, from dedicated project teams to vigilant steering boards, ensuring continuous alignment with your evolving objectives.

By implementing a fully integrated 3D product development process, fashion companies can unlock the benefits of designing digitally, including faster time-to-market, cost savings, enhanced accuracy, work more sustainably by reducing prototypes, and increased competitiveness in the dynamic fashion landscape. At Metyis, we merge technology, processes, and people with our strategy and analytics teams to unlock the full potential of digital fashion.

The author behind the article

Constanze Ihring is a senior strategy consultant based in Germany with an international background and extensive knowledge of digital transformation projects. In the last few years, she has gained extensive knowledge of the fashion industry with a focus on digital fashion.